Learn All About The Flexible Circuits

Maintaining a high-quality standard is your first priority as a manufacturer of equipment for the military and aerospace industries. Furthermore, if there is a new technology that can be used to improve the quality of your electronics and the efficiency with which your PCBs can be manufactured, you should consider implementing it carefully. Flexible circuits are that technology if you’re curious. Read More

To begin with, let’s define flexible circuits.

Consider the impact of the technological innovations you’ve made recently. A fitness tracker or an adaptable lamp for late-night reading are two examples. Do you usually go around with a tablet computer or other mobile device? All of these gadgets almost certainly contain a bendable PCB.

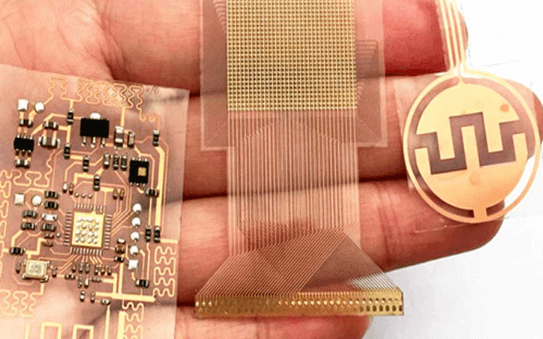

Electronics with flexible circuits can bend or flex to fit any application. The term “flexible electronics” is used to describe any type of electronic device that may be physically manipulated (folded, bent, rolled, stretched, etc.) without compromising its functionality. Adding electronic flexible circuits to your PCB assembly requires mounting electrical devices onto polyimide or other flexible high-performance plastic substrates. The PCB can be bent into place and then baked to permanently set the shape. Many sectors make heavy use of flexible PCB circuits because of the increased versatility (pardon the pun) they bring to PCB applications in fields like manufacturing, aircraft, food service, transportation, and the armed forces.

What are the Benefits of Including Flexible Circuits in a Printed Circuit Board Assembly?

You may be wondering, now that you have a better grasp of what flexible electronics are, what benefits a flexible circuit actually has over rigid boards. Read More

The use of flexible circuits in your PCB assembly can provide several advantages and has many possible uses.

Reduce product size and weight.

With the help of flexible circuitry, product size and weight can be reduced by increasing density and getting rid of unnecessary connections and wires. In rockets and spacecraft, for instance, electrical connections between subassemblies can replace cumbersome and inefficient wire harnesses. Flexible printed circuit boards (PCBs) can be bent to fit into small areas while still performing as reliably as their rigid counterparts.

Design and packaging enhancements.

In terms of product design and packaging, flexible circuits offer greater freedom because they can be folded. You can use a flex PCB to adapt your PCB assembly to a location that isn’t the standard size or form. If you’re working with an electronic contract manufacturer, the design team there may be able to offer you some leeway in terms of flex circuit size, shape, and component selection. Substituting components of varying sizes and purposes could save costs. Solar power, lighting in general, consumer, commercial, and military displays, and medical aid devices are just a few examples of markets where flexible circuits could have a significant impact.

Strengthened Resistance to Accidents on the Road

Because of their resistance to vibration and movement, flexible circuits find widespread application in the transportation sector and are a highly efficient option in aerospace and military manufacturing.

Maintain AS9100 and ISO 9001 standards.

Quality is paramount for AS9100 and ISO 9001 certified manufacturers. Flexible circuits can greatly enhance product quality by lowering the likelihood of wiring mistakes, doing away with the need for mechanical connectors, expanding the range of temperatures over which the product can function, enhancing reliability and impedance control, and bolstering signal quality. Even if your PCB assembly doesn’t need such certifications, you should nonetheless look for them. Your electrical contract manufacturer should adhere to and take quality seriously, as demonstrated by the fact that they maintain such standards. Independent quality audits are something that many ECMs do to prove their commitment to their clients. It’s a crucial step in making either a rigid or flexible printed circuit board.

Improve Your Adaptability

The use of flexible circuits allows for some items to become more flexible in response to their surroundings. As an example, Organic Light-Emitting Diodes (OLEDs) can be attached to pliable or curving surfaces. Additionally, they are able to function at lower temperatures. OLEDs are not only highly efficient but also exceedingly adaptable, making them useful in a wide variety of contexts.

As you can see, using flexible circuits in your PCB construction has many advantages. There are just too many real-world benefits enjoyed by items with flexible circuits as opposed to those with rigid circuits to count.